Building an outdoor kitchen requires careful material selection to ensure your investment withstands weather extremes and daily use. There are several options for outdoor kitchen countertops — natural stone, concrete and tile are the most popular, but choosing the right materials goes far beyond just countertops.

This guide covers every component of outdoor kitchen construction, from structural frames to finishing touches, helping you make informed decisions that will last for decades.

Why Material Selection Matters for Outdoor Kitchens

Outdoor kitchens face unique challenges that indoor spaces never encounter. Rain, snow, UV rays, temperature swings, and humidity can destroy poorly chosen materials within just a few seasons.

The right materials protect your investment and ensure safety around high-heat appliances like built-in grills. Poor material choices can lead to structural failures, fire hazards, and expensive repairs.

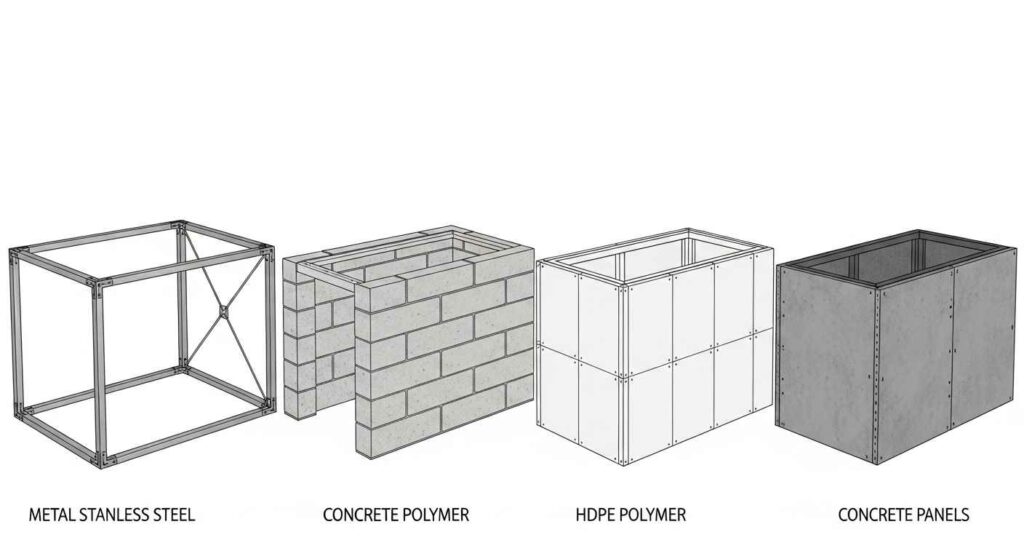

Outdoor Kitchen Structural Frame Materials

Metal Frames

Metal frames are the most popular option for outdoor kitchen construction due to their availability and structural strength.

Advantages:

- Lightweight and easy to transport

- Efficient use of space with ample interior cavity

- High weight capacity when using proper gauge metal

- Wide availability from manufacturers

Disadvantages:

- Vulnerable to moisture damage and corrosion

- Requires corrosion-resistant treatments in humid climates

- Challenging for DIY installation

- Not ideal for coastal areas with salt air

Best for: Dry climates like Southern California and Arizona

Concrete Block (CMU)

Concrete masonry units provide exceptional durability but come with significant installation challenges.

Advantages:

- Excellent weather resistance in any climate

- Non-combustible for safety around grills

- Extremely durable and long-lasting

- No corrosion concerns

Disadvantages:

- Heavy and requires structural footings

- Expensive professional installation required

- Limited interior space for appliance access

- Time-consuming and messy installation process

Best for: Permanent installations where weight isn’t a concern

HDPE and Marine-Grade Polymers

Manufacturers like Werever are leading the charge with HDPE (High-Density Polyethylene), a marine-grade polymer known for its exceptional durability, UV resistance, and low maintenance.

Advantages:

- Immune to rust, rot, and corrosion

- Low maintenance requirements

- Lightweight installation

- No structural footings needed

- Built-in finish eliminates additional cladding

Disadvantages:

- Combustible material requiring insulated jackets

- Limited customization options

- Higher upfront cost than basic metal frames

- Fewer design choices compared to traditional materials

Best for: Coastal areas and high-moisture climates

Concrete Panels (Modern Solution)

Engineered concrete panels represent the newest advancement in outdoor kitchen construction, combining the durability of concrete with modern convenience.

Advantages:

- Non-combustible for maximum safety

- 100-year durability rating

- Quick assembly (hours instead of days)

- Wide interior cavity prevents heat buildup

- Integrated finish eliminates delamination risks

- Suitable for any climate

Disadvantages:

- Limited availability from specialized manufacturers

- Higher initial investment

- Newer technology with less long-term data

Best for: Anyone seeking the ultimate in durability and convenience

Essential Substrate Materials

Cement Board

For metal and wood frames, cement board provides the surface for attaching finishing materials.

Key characteristics:

- Made from cement, water, silica, and reinforcing fibers

- Water-resistant but not waterproof

- Originally designed for interior bathroom use

- Can sustain damage in freeze/thaw cycles

Important note: Many cement board brands don’t recommend ground contact with their product… Which raises some concern about how water resistant they truly are.

Use cement board only in moderate climates and ensure proper drainage around the structure.

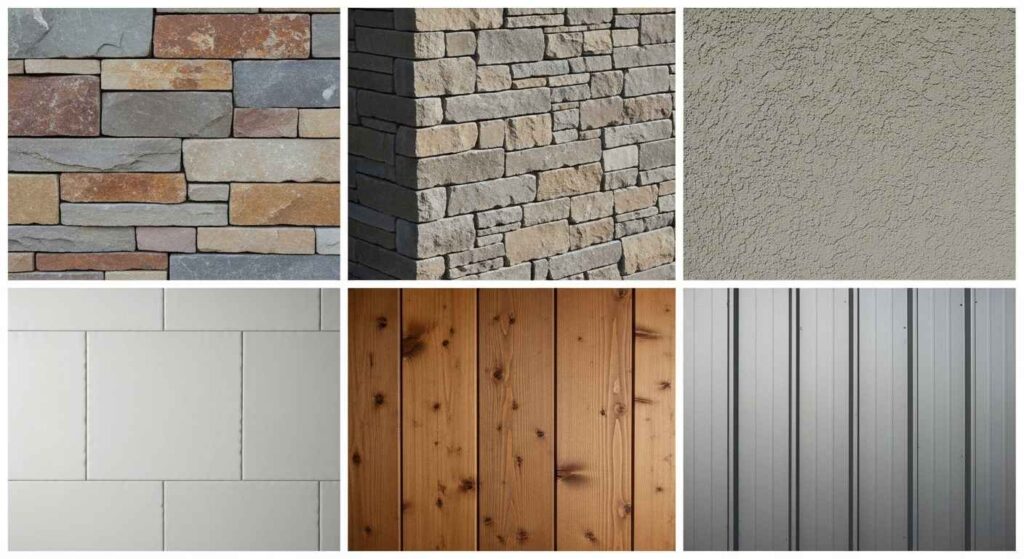

Outdoor Kitchen Cladding and Finish Materials

Natural Stone Veneer

Natural stone is a top choice for outdoor kitchens due to its durability and timeless appeal. Options like slate or travertine offer excellent resistance to the elements while maintaining a sophisticated appearance.

Popular options:

- Granite: Dense and stain-resistant

- Slate: Natural slip resistance

- Travertine: Natural beauty with proper sealing

- Bluestone: Excellent for formal designs

Maintenance: Requires periodic sealing to prevent staining and water damage.

Manufactured Stone Veneer

Provides the appearance of natural stone at a fraction of the cost.

Benefits:

- Consistent appearance and sizing

- Lower cost than natural stone

- Lighter weight for easier installation

- Better uniformity for modern designs

Stucco Finish

For the budget-conscious, stucco may be your best bet. It’s an inexpensive outdoor kitchen siding option that has become a popular choice in recent years.

Climate considerations:

- Excellent for warm, dry climates

- Poor performance in freeze/thaw conditions

- Susceptible to cracking in high-moisture areas

- Popular in Florida and California

Tile Cladding

Tile offers unlimited design possibilities but requires careful climate consideration.

Pros:

- Extensive color and pattern options

- DIY-friendly installation

- Easy to clean when properly maintained

Cons:

- Fragile in extreme weather

- Grout maintenance requirements

- Risk of tiles popping off in temperature fluctuations

Best use: Covered outdoor kitchens in moderate climates

Outdoor Kitchen Countertop Materials

Granite Countertops

Granite remains the gold standard for outdoor kitchen countertops.

Advantages:

- Extremely durable and heat-resistant

- Natural beauty that complements outdoor settings

- Stain-resistant when properly sealed

- High resale value

Considerations:

- Dark colors absorb heat in direct sunlight

- Requires periodic sealing

- Professional installation recommended

- Higher initial cost

Concrete Countertops

Concrete countertops also provide a natural look and feel to your outdoor kitchen. Concrete countertops also avoid some of the pitfalls of natural materials. They can be structurally reinforced.

Benefits:

- Can be reinforced internally for strength

- Custom colors and textures available

- Integrated sinks and features possible

- More affordable than natural stone

Drawbacks:

- Porous surface requires regular sealing

- Susceptible to scratches and stains

- May develop hairline cracks over time

Natural Stone Options

Bluestone and Limestone:

- Beautiful natural appearance

- Good heat resistance

- Requires regular sealing due to porosity

- Risk of cracking in extreme temperature changes

Soapstone:

- Naturally non-porous

- No sealing required

- Beautiful gray coloring

- Softer material prone to scratches

Porcelain and Ceramic Tile

Advantages:

- Budget-friendly option

- Unlimited design possibilities

- Heat and stain resistant when quality materials used

Disadvantages:

- Grout lines collect bacteria and stains

- Individual tiles can crack or pop off

- Difficult to maintain sanitary food prep surfaces

- Poor performance in freeze/thaw climates

Materials to Avoid for Countertops

Quartz:

- Yellows under UV exposure

- Poor moisture resistance

- Better suited for indoor use

Stainless Steel:

- Becomes extremely hot in direct sunlight

- Shows fingerprints and scratches easily

- Better reserved for appliances only

Outdoor Kitchen Cabinet Materials

Stainless Steel Cabinets

In our experience, stainless steel is the go-to for professionals in outdoor kitchen design, and it’s easy to see why. Its resilience against rust and ease of maintenance make it a premium choice, especially in coastal areas where saltwater can be brutal on lesser materials.

Quality indicators:

- 304-grade stainless steel minimum

- Welded corners instead of mechanical fasteners

- Proper drainage systems built in

- Marine-grade hardware

Marine-Grade Polymer Cabinets

Kitchen cabinets will need to be able to stand up to moisture, mold, heat, rust and dirt. The main options for cabinetry are stainless steel, marine-grade polymer or timber.

HDPE characteristics:

- Completely weather-resistant

- No rusting or corrosion

- Easy cleaning and maintenance

- Available in multiple colors

- Recyclable and environmentally friendly

Aluminum Cabinets

Benefits:

- Lightweight yet strong

- Natural corrosion resistance

- Powder coating options for color

- Better value than stainless steel

Considerations:

- Lower quality than stainless steel

- Limited design options

- May dent more easily than steel

Wood Cabinets (Not Recommended)

Wood outdoor kitchen cabinets have poor weather resistance. Since these aren’t waterproof outdoor kitchen cabinets, you’ll quickly find yourself dealing with cracking, warping, and potential fire hazards near grills.

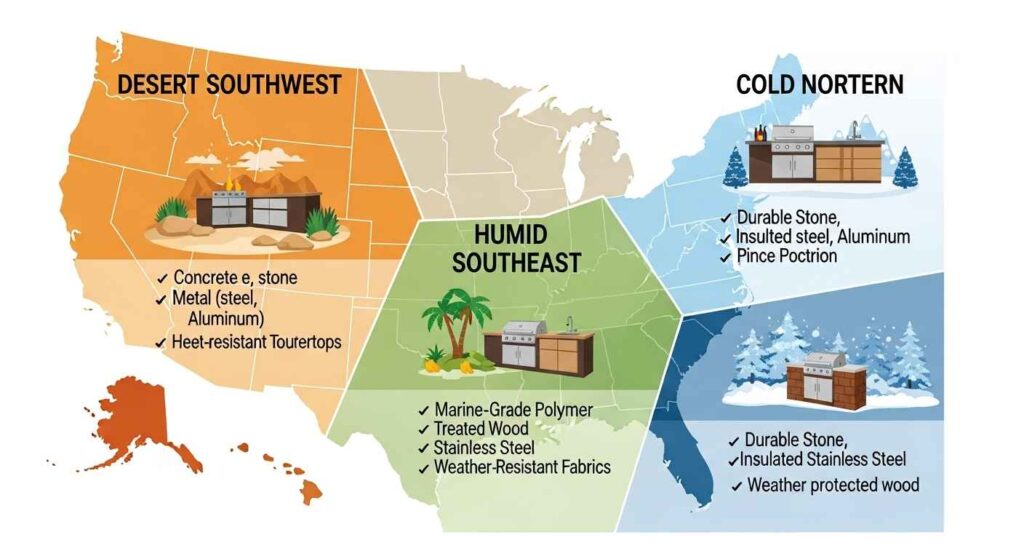

Climate-Specific Material Recommendations

Hot, Dry Climates (Southwest US)

Best choices:

- Metal frames with proper coating

- Stucco or stone veneer cladding

- Granite or concrete countertops

- Light-colored materials to reflect heat

Avoid:

- Dark materials that absorb excessive heat

- Materials prone to thermal expansion

Humid, High-Moisture Areas (Southeast US, Coastal)

Best choices:

- HDPE polymer or concrete construction

- Stainless steel or polymer cabinets

- Non-porous countertops (granite, engineered stone)

- Excellent drainage systems

Avoid:

- Untreated metal frames

- Porous materials without proper sealing

- Wood components

Freeze/Thaw Climates (Northern US, Canada)

Best choices:

- Concrete or polymer construction

- Non-porous, crack-resistant materials

- Proper insulation and drainage

- Materials with low thermal expansion

Avoid:

- Metal frames without treatment

- Tile applications

- Porous stone without proper sealing

Flooring Materials for Outdoor Kitchens

The surface of your outdoor entertaining area will be one of the most important considerations in your design process. Each possible surface has pros and cons that should be evaluated. Brick, cement, stone, wood, and tile all offer viable options.

Natural Stone Flooring

Flagstone:

- Natural slip resistance

- Beautiful irregular patterns

- Requires sealing in freeze climates

- Higher cost but exceptional durability

Travertine:

- Naturally cool surface

- Good for hot climates

- Requires regular sealing

- Can be slippery when wet

Concrete Flooring

Stamped concrete:

- Mimics expensive stone at lower cost

- Can be colored and textured

- Requires proper drainage

- May crack in freeze/thaw areas

Polished concrete:

- Modern, sleek appearance

- Easy to clean and maintain

- Can become slippery when wet

- Shows dirt and stains easily

Brick and Pavers

Clay brick:

- Classic appearance

- Natural slip resistance

- Requires sand base and proper drainage

- Individual units can shift over time

Concrete pavers:

- Uniform appearance

- Easy replacement of damaged units

- Many color and pattern options

- Requires proper base preparation

Safety Considerations for Material Selection

Fire Safety

All materials near cooking appliances must be non-combustible. This includes:

- Frame materials

- Cladding within 3 feet of grills

- Countertop materials

- Cabinet construction

Structural Safety

Weight considerations:

- Concrete construction requires proper footings

- Deck installations need structural evaluation

- Countertop support must handle heavy materials

Ventilation requirements:

- Interior cavities need airflow to prevent heat buildup

- Gas appliances require proper venting

- Avoid enclosed designs that trap heat

Maintenance Requirements by Material Type

Low-Maintenance Options

HDPE polymer:

- Periodic cleaning with soap and water

- No sealing or special treatments needed

- UV-stable colors won’t fade

Stainless steel:

- Regular cleaning to prevent water spots

- Occasional stainless steel cleaner application

- Check fasteners annually

Moderate-Maintenance Materials

Sealed natural stone:

- Annual sealing required

- Regular cleaning with pH-neutral cleaners

- Immediate cleanup of stains

Concrete:

- Re-sealing every 2-3 years

- Regular cleaning and stain removal

- Minor crack repairs as needed

High-Maintenance Options

Wood (not recommended):

- Annual staining or sealing

- Regular pest inspections

- Replacement of damaged boards

Tile with grout:

- Regular grout cleaning and sealing

- Individual tile replacement as needed

- Annual deep cleaning

Cost Analysis: Investment vs. Value

Budget-Friendly Options ($15,000-$25,000)

- Metal frame construction

- Stucco or basic stone veneer finish

- Concrete or tile countertops

- Basic stainless steel appliances

Mid-Range Investment ($25,000-$50,000)

- HDPE polymer or treated metal construction

- Natural stone veneer or quality manufactured stone

- Granite or engineered stone countertops

- Quality stainless steel appliances and cabinets

Premium Investment ($50,000+)

- Concrete panel or custom masonry construction

- High-end natural stone finishes

- Custom concrete or premium granite countertops

- Professional-grade appliances and custom storage

Consider the long-term value: spending more on quality materials upfront often costs less than replacing inferior materials every few years.

Installation Considerations

DIY-Friendly Materials

HDPE modular systems:

- Pre-fabricated components

- Simple assembly processes

- Detailed instructions provided

- Minimal tools required

Metal frame kits:

- Pre-cut components

- Basic welding or bolting

- Moderate skill level required

- Professional help recommended for complex designs

Professional Installation Required

Concrete construction:

- Specialized equipment needed

- Structural engineering considerations

- Permit requirements in most areas

- Significant site preparation

Custom masonry work:

- Skilled tradesperson required

- Extended timeline for completion

- Weather-dependent installation

- Higher labor costs

Latest Trends and Innovations in Outdoor Kitchen Materials

Sustainable Materials

Eco-conscious homeowners increasingly choose materials with:

- Recycled content (recycled aluminum, composite materials)

- Local sourcing to reduce transportation impact

- Long lifespan to minimize replacement needs

- End-of-life recyclability

Smart Material Technologies

Self-healing concrete:

- Contains bacteria that repair small cracks automatically

- Extends lifespan significantly

- Currently in development for residential use

Advanced polymer composites:

- Combining multiple materials for enhanced properties

- Improved UV resistance and color retention

- Better thermal properties

Design Integration

Modern outdoor kitchens blend seamlessly with home architecture through:

- Color-matched materials

- Consistent design themes

- Indoor-outdoor material continuity

Common Mistakes to Avoid

Material Selection Errors

- Choosing indoor materials for outdoor use

- Standard plywood instead of marine-grade

- Interior tile without freeze resistance

- Regular steel instead of stainless

- Ignoring local climate conditions

- Using metal frames in high-humidity areas

- Selecting porous stone in freeze climates

- Choosing heat-absorbing materials in desert regions

- Prioritizing appearance over function

- Selecting materials that look good but require excessive maintenance

- Choosing trendy options without proven durability

- Ignoring safety requirements for combustible materials

Installation Mistakes

- Inadequate drainage planning

- Poor water management leads to material failure

- Insufficient slope for water runoff

- Missing vapor barriers where needed

- Improper structural support

- Underestimating weight requirements

- Skipping foundation work for heavy materials

- Inadequate fastening systems

Conclusion: Making the Right Material Choices

Building a successful outdoor kitchen requires balancing multiple factors: climate resistance, safety, maintenance requirements, budget, and aesthetic preferences.

Far and away, concrete is the best material for use in an outdoor kitchen. It is non-combustible, won’t corrode, won’t rust, and won’t be affected by moisture, snow, ice, or inclement weather.

For most homeowners, the ideal outdoor kitchen combines:

- Non-combustible structural materials (concrete, steel, or quality polymers)

- Weather-appropriate finishes for your specific climate

- Durable, low-maintenance countertops

- Quality stainless steel or polymer cabinetry

Remember that your outdoor kitchen is a long-term investment. Choosing quality materials upfront prevents costly repairs and ensures years of enjoyable outdoor cooking and entertaining.

Ready to start planning your outdoor kitchen? Check out our affordable backyard makeover ideas under $1000 for budget-friendly ways to begin your outdoor living transformation, or explore our pergola design ideas for backyards to create the perfect covered cooking space.

Key Takeaways:

- Climate is the most important factor in material selection

- Non-combustible materials are essential for safety

- Quality materials cost more upfront but save money long-term

- Proper installation is as important as material choice

- Regular maintenance extends the life of any outdoor kitchen

Planning an outdoor kitchen project? Consider starting with our guide to small patio design inspiration to maximize your outdoor space potential.